Products

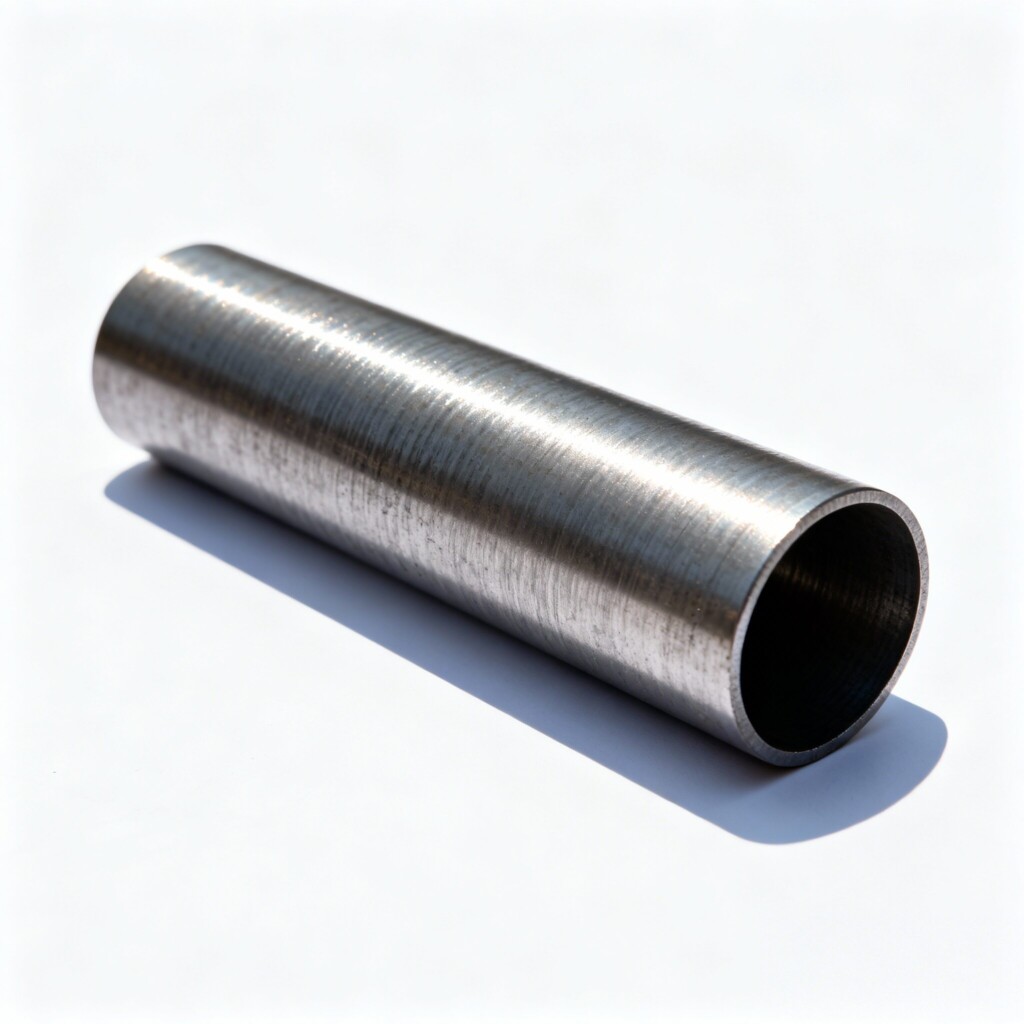

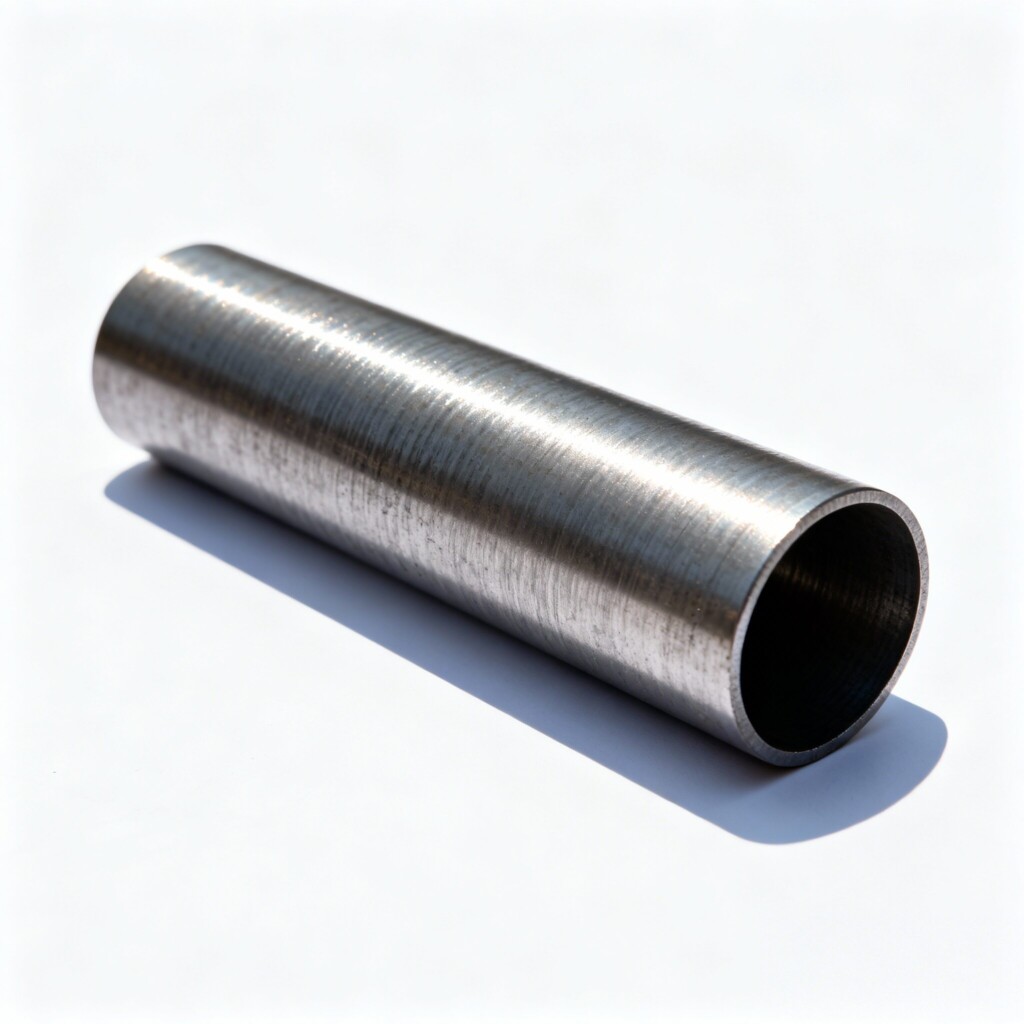

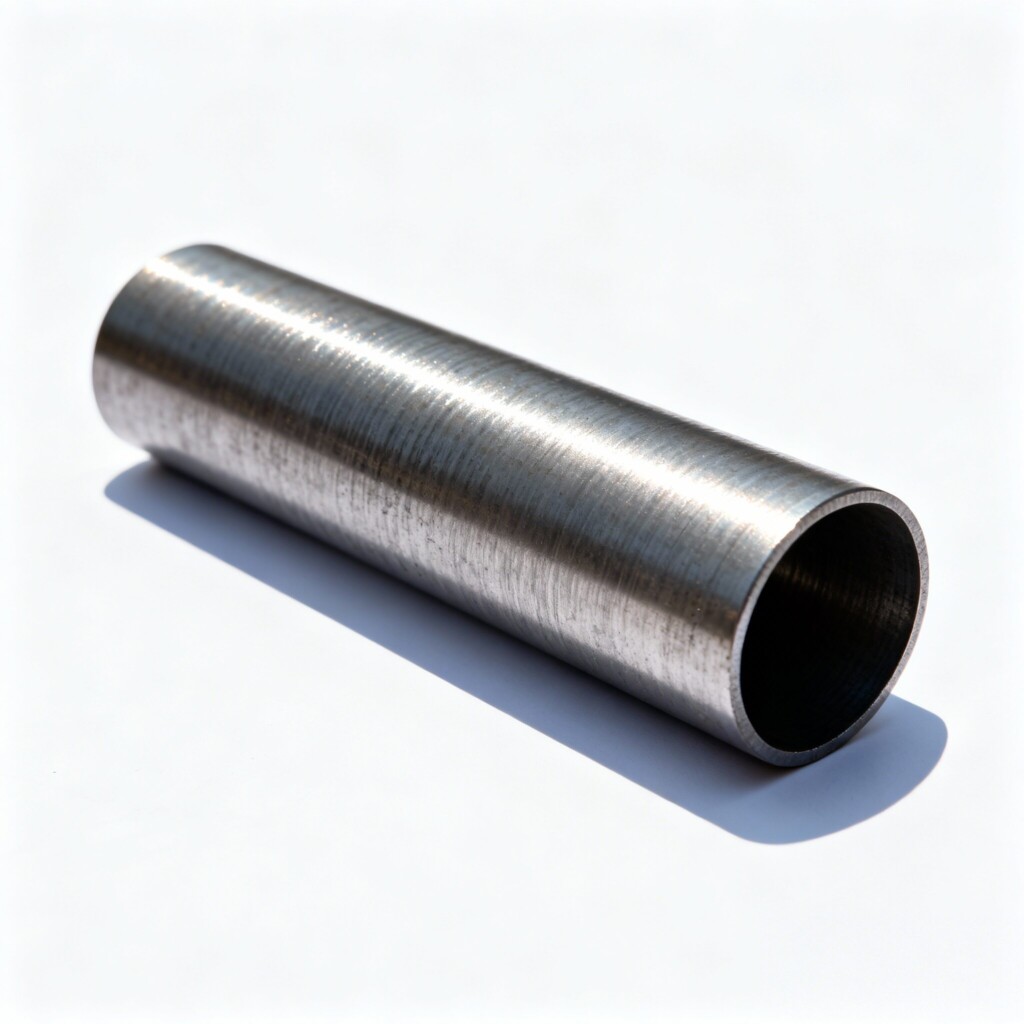

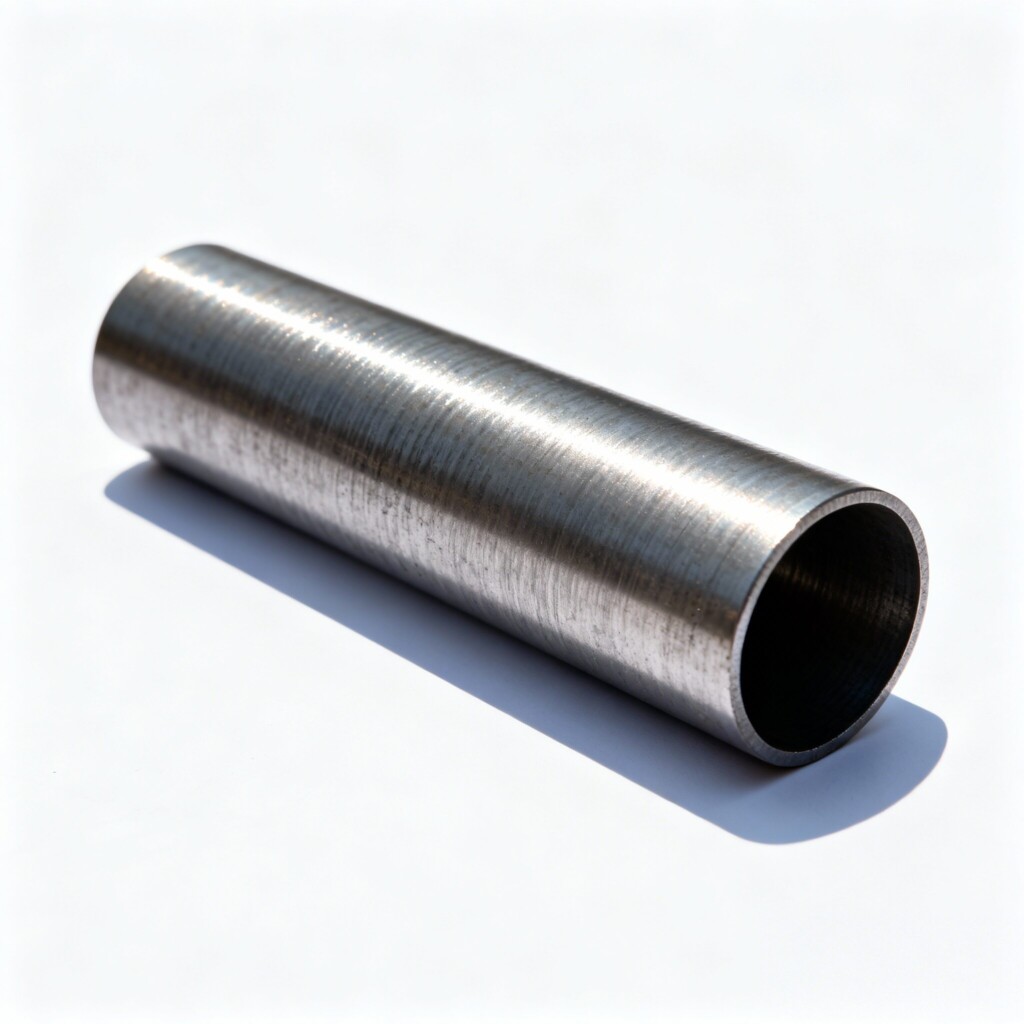

Superalloy (Plate, Rod & Tube)

Superalloy, also known as High Temperature Alloy or Heat Resistant Alloy, is a class of advanced metal materials designed to operate reliably under extreme temperatures, high mechanical stress, and corrosive environments.

Our high temperature alloys are supplied in plate, rod, and tube forms, covering a wide range of industrial applications such as aerospace, power generation, chemical processing, and high-temperature equipment manufacturing.

The products are available in nickel-based, iron-based, and cobalt-based alloys, meeting international standards and customized requirements.

Available Alloy Types

Nickel-Based High Temperature Alloy

Nickel-based superalloys offer exceptional high-temperature strength, oxidation resistance, and corrosion resistance.

They maintain stable mechanical performance at temperatures up to 1100°C, making them ideal for critical and long-life components.

Typical grades: Inconel 718 / 625, Hastelloy C276, customized nickel alloys.

Iron-Based High Temperature Alloy

Iron-based high temperature alloys provide balanced performance with good strength, corrosion resistance, and cost efficiency.

They are widely used in industrial furnaces, power plants, and thermal processing systems operating at medium to high temperatures.

Cobalt-Based High Temperature Alloy

Cobalt-based superalloys feature excellent wear resistance, thermal stability, and strength retention under severe thermal cycling.

They are suitable for high-wear and high-temperature environments such as turbine components and hot-section parts.

Product Forms & Supply Range

– Plate / Sheet – For fabrication, heat-resistant structures, and pressure parts

– Rod / Bar – For machining, forging, shafts, and high-strength components

– Tube / Pipe – For heat exchangers, high-temperature fluid systems, and pressure applications

All forms can be supplied according to customer specifications and drawings.

Key Features & Advantages

– Excellent high-temperature strength and structural stability

– Superior oxidation and corrosion resistance

– Outstanding creep resistance under long-term heat exposure

– Reliable performance in harsh industrial environments

– Suitable for machining, welding, forging, and fabrication

– Long service life and reduced maintenance cost

Typical Applications

– Aerospace and aircraft engine components

– Gas turbines and power generation equipment

– Chemical and petrochemical processing plants

– Heat exchangers and high-temperature piping systems

– Industrial furnaces and thermal treatment equipment

– Automotive turbochargers and exhaust systems

|

Item

|

Plate / Sheet

|

Rod / Bar

|

Tube / Pipe

|

|

Product Form

|

Plate / Sheet

|

Round Bar / Rod

|

Seamless / Welded Tube

|

|

Alloy Type

|

Ni-based / Fe-based / Co-based

|

Ni-based / Fe-based / Co-based

|

Ni-based / Fe-based / Co-based

|

|

Thickness / Diameter

|

3 – 120 mm

|

6 – 500 mm

|

OD 10 – 500 mm

|

|

Length / Width

|

Customized

|

Fixed or Random

|

Customized

|

|

Wall Thickness

|

—

|

—

|

1 – 30 mm

|

|

Surface Finish

|

Hot rolled, cold rolled, pickled

|

Black, peeled, polished

|

Pickled, bright, annealed

|

|

Standard

|

ASTM, AMS, DIN, EN, JIS

|

ASTM, AMS, DIN, EN, JIS

|

ASTM, AMS, DIN, EN, JIS

|

|

Heat Treatment

|

Solution annealed / As required

|

Solution annealed / As required

|

Solution annealed / As required

|

|

Certification

|

MTC EN 10204 3.1

|

MTC EN 10204 3.1

|

MTC EN 10204 3.1

|