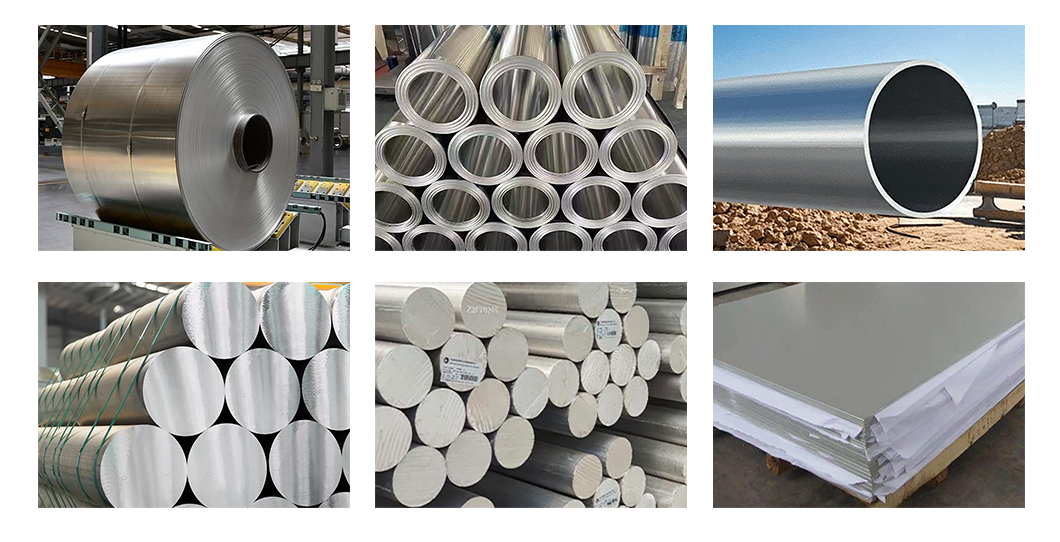

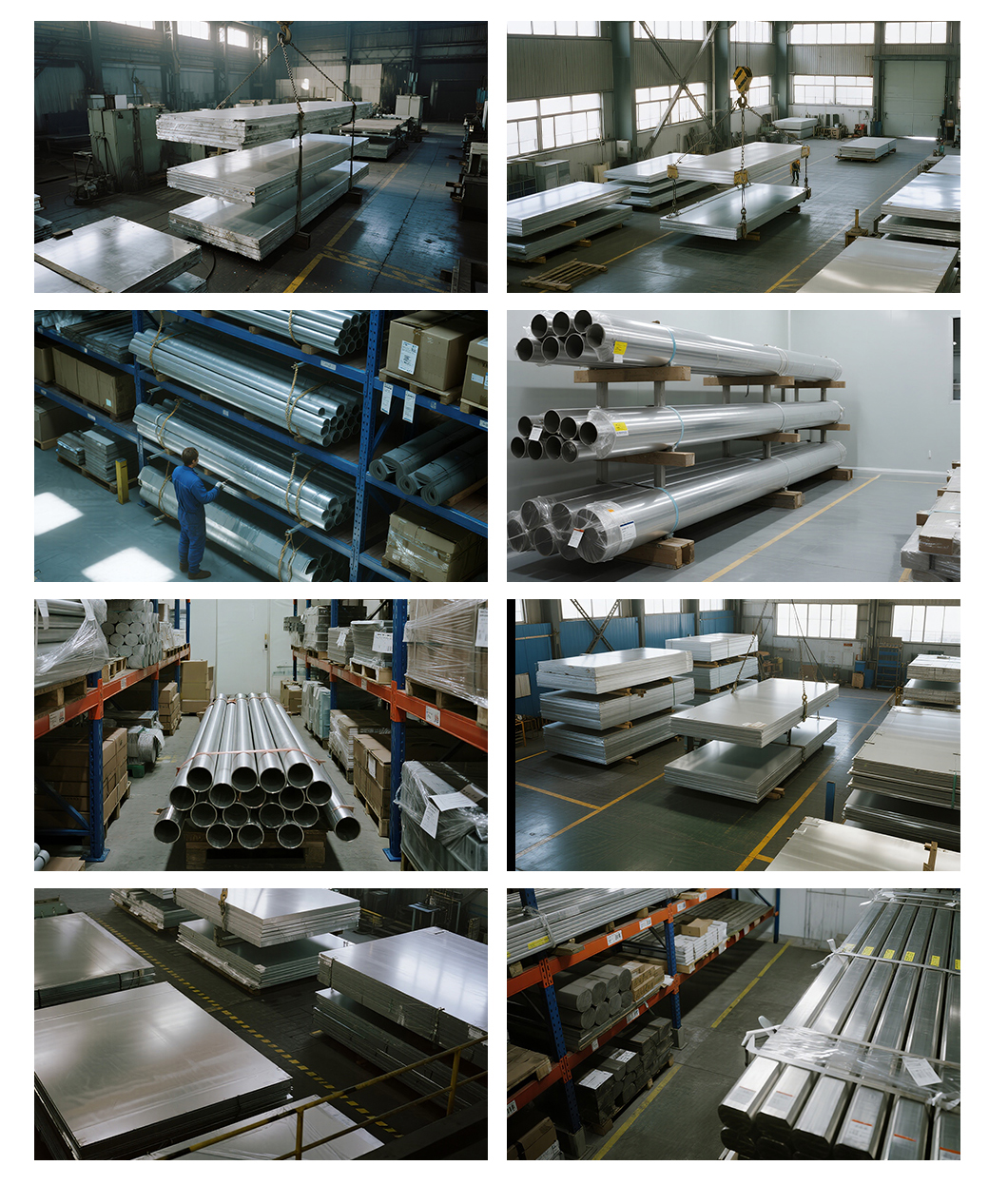

Products

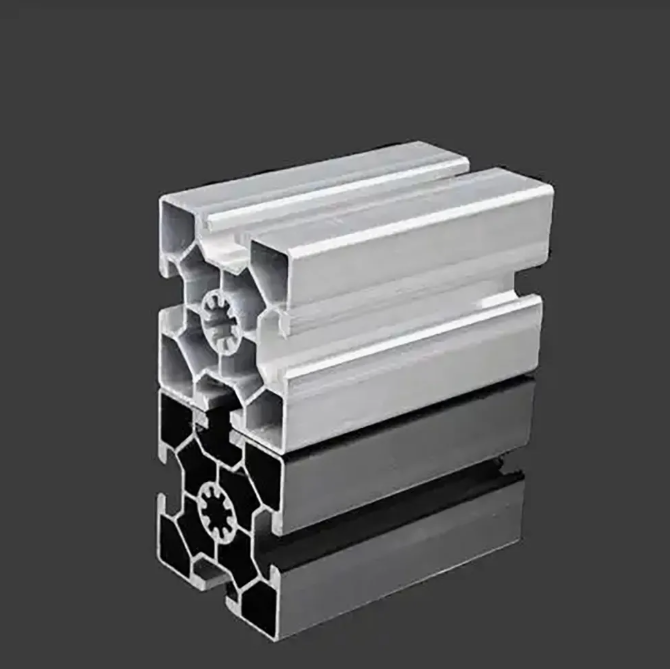

Shape : As per customized drawing

Material available : Aluminum alloy 6000series

Temper : T3-T8

Type : Window & Door Aluminium Profile, Decoration Aluminium Profile, Heat Sink Aluminium Profile, Glass Wall Aluminium Profile, Transport Aluminium Profile, Industrial Aluminium Profile, Frame ,Pipe&Tube,Vaporizer

Categories: Aluminium Alloy Series

1. (Melting & Casting) Aluminum ingots and alloying elements are melted in a furnace, refined to remove impurities and gas, then cast into cylindrical billets.

2. (Homogenization) Billets are heated in a homogenizing furnace to achieve a uniform microstructure and chemical composition, relieving internal stresses.

3. (Die Preparation) The high-strength steel die, manufactured to the profile’s cross-section, is preheated to a specific temperature for extrusion.

4. (Extrusion) Core Process: The heated billet is pushed through the die opening by a hydraulic ram, forcing it to take the shape of the die’s cross-section.

5. (Quenching) The extruded profile is rapidly cooled (with air or water) to “freeze” the metallic structure and achieve higher strength.

6. (Stretching & Straightening) The profile is stretched to straighten it, correct twisting, and align the grains to improve mechanical properties.

7. (Sawing) The straightened long bar is cut to the required commercial lengths.

8. (Aging) Profiles are heated in an aging oven for a period of time to precipitate strengthening compounds and achieve final mechanical properties (T5, T6 temper).

9. (Surface Treatment)(Anodizing)(Powder Coating)(Electrophoresis). Profiles undergo surface treatment as required. Anodizing (most common for corrosion/wear resistance and coloring), Powder Coating, or Electrophoresis are typical processes.

10. (Inspection & Packaging) Final inspection of dimensions, surface quality, and mechanical properties. Qualified products are packaged with protective film for shipment.