Products

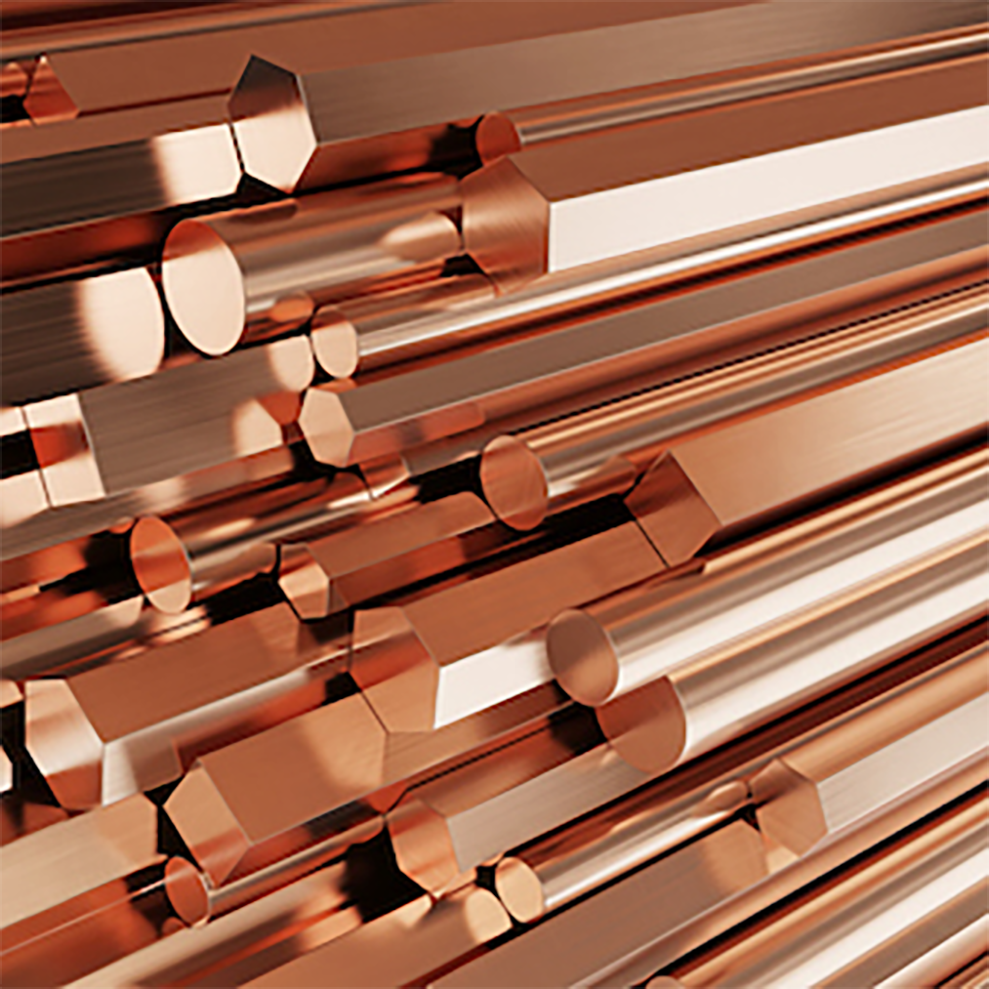

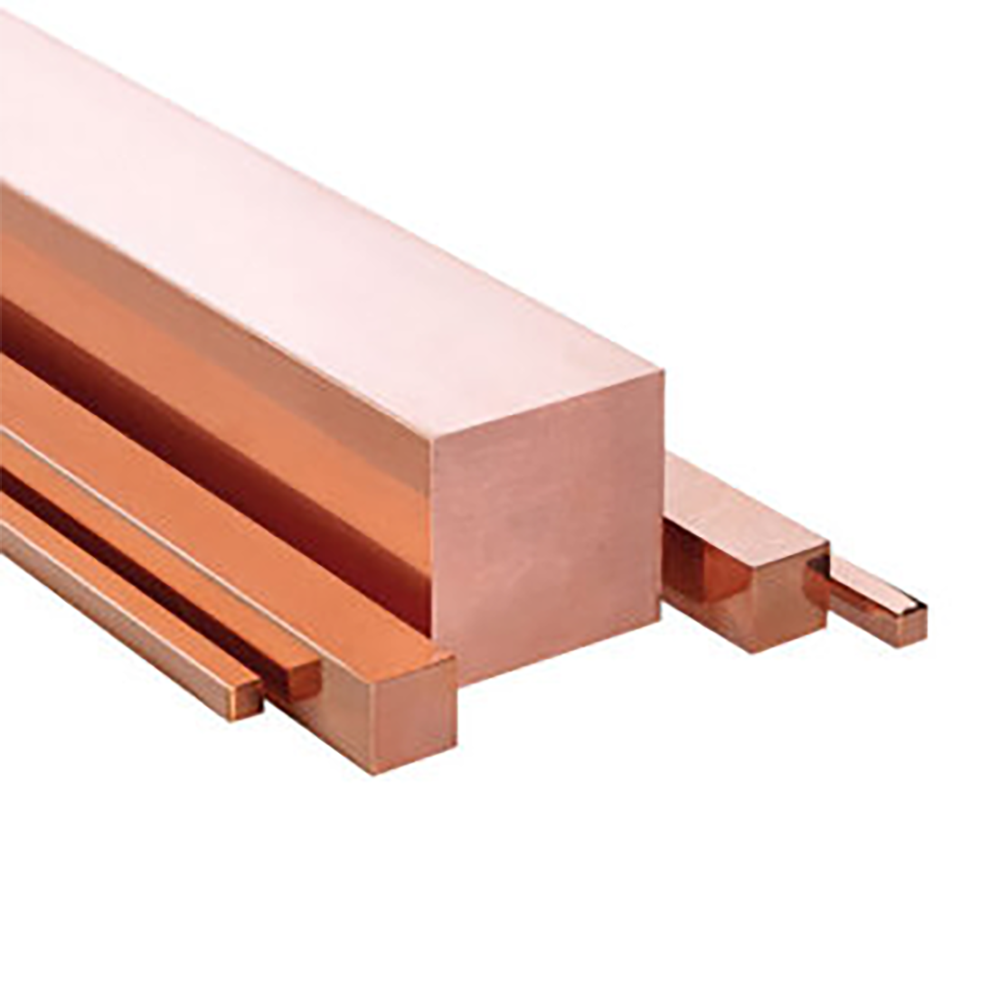

Shape Round Bar

Surface Treatment Polished

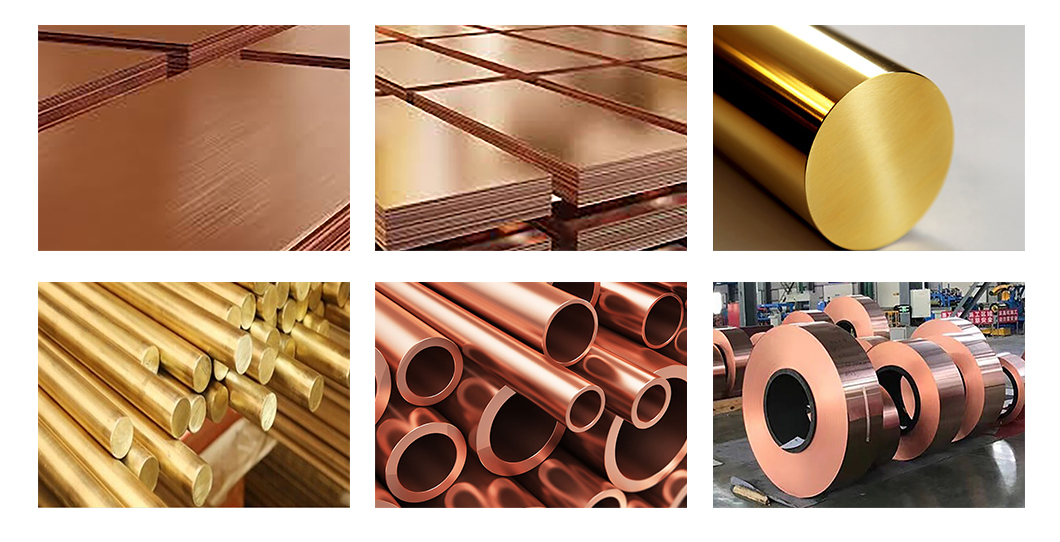

Material Type Pure Copper, Brass, White Copper, Bronze

Application Automotive Components, Industrial Machinery…

Common Grades T1, T2, T3, Tu1, Tu2, H65, H68, Hpb59-1, B19, B25

Categories: Copper Alloy Series

|

Pure copper

|

|

|

Common grades

|

T1, T2, T3, TU1, TU2

|

|

Characteristics

|

Conductive

|

|

Common uses

|

Electrical switches, motor coils, electronic components, air conditioning piping, soft welding gun heads

|

|

Brass

|

|

|

Common grades

|

H59, H62, H65, H68, HPb59-1 (easy-to-machine brass)

|

|

Characteristics

|

High strength, wear-resistant, resistant to water vapor corrosion

|

|

Common uses

|

Architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, military supplies

|

|

White copper

|

|

|

Common grades

|

B19, B25, BFe10-1-1, BZn15-20, BA13-3

|

|

Characteristics

|

Stable physical properties at room temperature

|

|

Common uses

|

Medical equipment, precision instruments, thermocouples, clock parts, eyeglass frames

|

|

Bronze

|

|

|

Common grades

|

QCr 0.5, QCr 0.6-0.4-0.05, QSn 4-3, QSn 6.5-0.4, QSn 7-0.2, QAl 5, QAl 9-2, QAl 10-4-4, QSi 3-1, QSi 3.5-3-1.5, QMn 1.5, QMn 5, QCd 1

|

|

Characteristics

|

Different formulations based on hardness, strength, elasticity, high-temperature conductivity, etc.

|

|

Common uses

|

Lamp spring clips, switch spring clips, resistance welding electrode materials (rolling welders, butt welders, contact welders, riveting welders), chromium-zirconium copper, beryllium-cobalt copper

|

|

CuNi2 NC005

|

1

|

2

|

4

|

6

|

8

|

3

|

10

|

14

|

|

|

CN3W

|

CN5W

|

CN7W

|

CN10W

|

CN12W

|

QMn3

|

CN15W

|

CN20W

|

||

|

TYPE

|

CuNi1

|

CuNi2CuNi4

|

CuNi6

|

CuNi8

|

CuMn3

|

CuNi10

|

CuNi14

|

||

|

NC003

|

NC005NC007

|

NC010

|

NC012

|

MC012

|

NC015

|

NC020

|

|||

|

Composition(%)

|

Cu

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

|

Mn

|

—

|

—

|

—

|

—

|

—

|

3

|

—

|

0.3

|

|

|

Ni

|

1

|

2

|

4

|

6

|

8

|

10

|

14.2

|

||

|

Max.continuous operating temperatureC

|

200

|

200

|

200

|

220

|

250

|

200

|

250

|

300

|

|

|

μΩ ·m(20℃)Resistivity

|

0.03±10%

|

0.05±10%

|

0.07±10%

|

0.10±10%

|

0.12±10%

|

0.12±10%

|

0.15±10%

|

0.20±5%

|

|

|

×105/℃

(20-600℃) Resistance-temperaturecoefficient |

<100

|

<120

|

<50

|

<60

|

<57

|

<38

|

<50

|

<38

|

|

|

Thermovoltage tocopperat20℃inμV/K

|

-8

|

-12

|

-12

|

-18

|

-22

|

–

|

-25

|

-28

|

|

|

Mean coefficient oflinearthermal expansion,in10/K,at a temperaturebetween20 ℃and400℃

|

17.5

|

17.5

|

17.5

|

17.5

|

17.5

|

18

|

17.5

|

17.5

|

|

|

Thermal conductance at20℃W/mK

|

145

|

130

|

130

|

92

|

75

|

84

|

59

|

48

|

|

|

Specific heat capacityat20℃J/gK

|

0.38

|

0.38

|

0.38

|

0.38

|

0.38

|

0.39

|

0.38

|

0.38

|

|

|

Densityat20℃(g/cm³)

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

|

|

Melting temperaturein℃

|

1085

|

1090

|

1090

|

1095

|

1097

|

1050

|

1100

|

1115

|

|

|

Min.tensile strengthin N/mm²

|

210

|

220

|

220

|

250

|

270

|

290

|

290

|

310

|

|

|

% Elongation

|

25

|

25

|

25

|

25

|

25

|

25

|

25

|

25

|

|

|

CuNi2 NC005

|

19

|

23

|

30

|

34

|

44

|

|

|

CN25W

|

CN30W

|

CN35W

|

CN40W

|

CN50W

|

||

|

TYPE

|

CuNi19

|

CuNi23

|

CuNi30

|

CuNi34

|

CuNi44

|

|

|

NC025

|

NC030

|

NC035

|

NC040

|

NC050

|

||

|

Composition(%)

|

Cu

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

|

Mn

|

0.5

|

0.5

|

1

|

1

|

1

|

|

|

Ni

|

19

|

23

|

30

|

34

|

44

|

|

|

Max.continuous operating temperatureC

|

300

|

300

|

350

|

350

|

400

|

|

|

μΩ ·m(20℃)Resistivity

|

0.25±5%

|

0.30±5%

|

0.35±5%

|

0.40±5%

|

0.49±5%

|

|

|

×105/℃

(20-600℃) Resistance-temperaturecoefficient |

<25

|

<16

|

<10

|

<-0

|

<-6

|

|

|

Thermovoltage tocopperat20℃inμV/K

|

-32

|

-34

|

-37

|

-39

|

-43

|

|

|

Mean coefficient oflinearthermal expansion,in10/K,at a temperaturebetween20 ℃and400℃

|

17.5

|

17.5

|

17

|

16

|

15

|

|

|

Thermal conductance at20℃W/mK

|

38

|

33

|

27

|

25

|

23

|

|

|

Specific heat capacityat20℃J/gK

|

0.38

|

0.38

|

0.39

|

0.4

|

0.41

|

|

|

Densityat20℃(g/cm³)

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

|

|

Melting temperaturein℃

|

1135

|

1150

|

1170

|

1180

|

1280

|

|

|

Min.tensile strengthin N/mm²

|

340

|

350

|

400

|

400

|

420

|

|

|

% Elongation

|

25

|

25

|

25

|

25

|

25

|

|

|

BMn3-12

|

|

|

Alloy Name

|

BMn3-12 (Manganese brass / Manganese bronze)

|

|

Common Grades (Nickel-based alloys reference)

|

Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35

|

|

Chemical Composition (GB/T 5231-2022)

|

Cu ≈ 87%; Mn 11.5–13.5%; Fe 0.2–0.5%; C ≤ 0.05%; Si 0.1–0.3%; P ≤ 0.005%; S ≤ 0.02%; Ni 2–3.5% (Ni+Co total); Pb ≤ 0.02%; Al ≤ 0.2%; Mg ≤ 0.03%

|

|

Physical Properties

|

Density: ~8.4 g/cm³; Melting range: 961–1011.2 °C; Thermal expansion coefficient: 16×10-6 K-1(at 100 °C); Thermal conductivity: 21.8 W/(m·K); Specific heat capacity: 0.408 J/(kg·K); Electrical resistivity: 0.435×10-6 Ω·m; Temperature coefficient of resistivity: 0.00003 °C-1

|

|

Mechanical Properties

|

High hardness and wear resistance with good toughness and corrosion resistance; After quenching & aging: Tensile strength ≥ 400 MPa; Yield strength ≥ 300 MPa

|

|

Application Fields

|

Heavy industry, construction machinery, transportation vehicles, energy equipment, aerospace, automotive; Suitable for heavy-load parts such as bearings, bushings, gears, gearboxes, hydraulic system components

|

|

Processing & Manufacturing

|

Processing methods: casting, forging, extrusion, cutting; Heat treatment: quenching and aging to improve mechanical properties; Good weldability with various welding techniques

|